Zhongke Anpu Face Masks Machine Catalog

A. Company Profile

Henan Zhongke Anpu Technology Co., Ltd. is located in Tanghe County, Henan Province. It was established in 2011. It is a scientific and technological enterprise integrating R & D, production, sales and service. The company's industrial park covers an area of 10 acres, with a total investment of 120 million RMB.

The company has a strong product research and development team as well as a comprehensive quality assurance system. It has more than ten years of experience in the wide-format printer market and has a deep understanding of various demands for each customer.

The company has won various honors such as Excellent Service Provider of Chinese Printer Industry, Excellent Enterprise of Chinese Printer Industry, Excellent Enterprise of National After-sales Service, Advanced technology enterprise, etc., and has been selected as a superior enterprise in intellectual property rights in Nanyang City. In the 7th China Innovation and Entrepreneurship Competition, he was rewarded as one of the most potential enterprise in the final round with excellent results from previous competition with over 100 enterprises.

The company cooperates with numbers of universities and scientific research units to develop printer control software and hardware. Starting from micro-piezo photo machines, UV flatbed printers and UV industrial flatbed printers have been developed into wall printers currently, which have developed 8 types of models and 22 products.

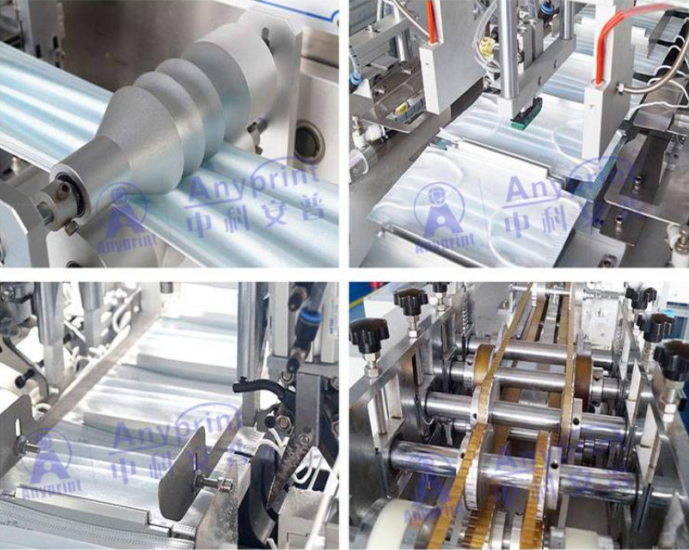

In February 2020, due to the severe epidemic situation of new coronavirus, the gap in the demand for masks was huge, and the company decided to invest in a research and development project for mask production equipment. The company's R & D department started the technical feasibility analysis of the project from 3rd February and reach the conclusion that the company is fully equipped with the ability to design and produce the mask machines. The general manager Mr. Qu and the head of R & D team went to Shanghai to get the existing production equipment operation status, mask production processes, core technical indicators, and technical requirements for new equipment. Within 14 days, the company shift the production line from printer to high-speed ear band mask machine with all effort of R&D team, and plans to complete the first batch of equipment delivery by 28th March.

B. Specification

HS-PM01 is a high speed fully automatic equipment that produce two disposable face mask every time. After the disinfected process, the product can reach the standard of surgical masks requirement.

Common medical masks consists with three layers of non-woven fabric: the inner layer is ordinary non-woven fabric, the outer layer is non-woven fabric with waterproof treatment, which is mainly used to prevent the liquid sprayed by patients, the middle layer is made by Polypropylene meltblown non-woven fabric to protect the user from virus. After production, it should be sterilized with ethylene oxide and left to stand for 7 days for volatile toxicity then it can be sealed and packed and shipped away.

C. Main Function

This equipment is mainly composed with three parts: a main body machine, a flap conveying system and two ear band welding machines. The main body machine will presses three layer of the fabric together and cut it to the shape of mask. After the mask body is output, it is conveyed to ear band machine through conveying system. The product is completed when the ear band being welded.

The production line is controlled by PLC and touch screen. The main conveyor belt is transported by single-phase motor, the stepping motor.

D. Main Feature

The equipment has good welding effect and low failure rate. It can reach 90-120 masks per minute, which can be continuously produced for 24 hours. It use computer PLC programming control with servo drive, highly automatic photoelectric detection of raw materials to avoid errors and reduce waste.

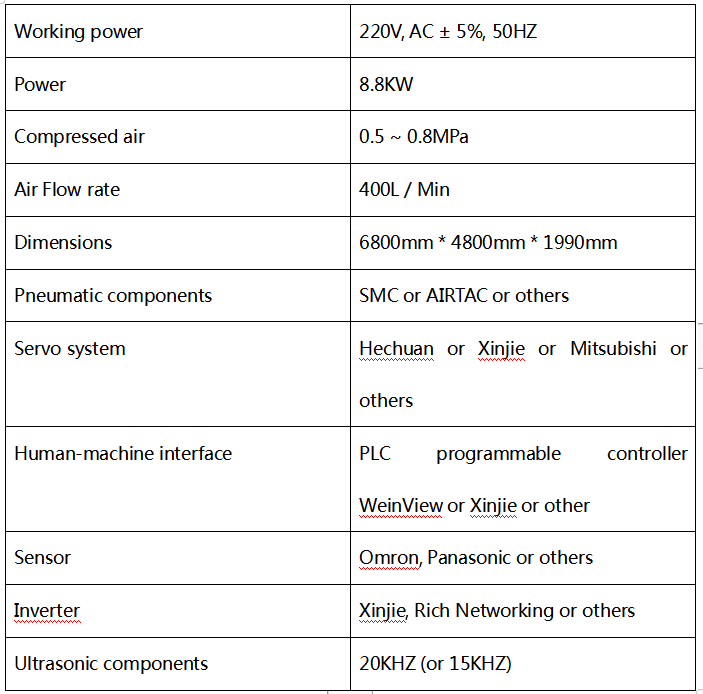

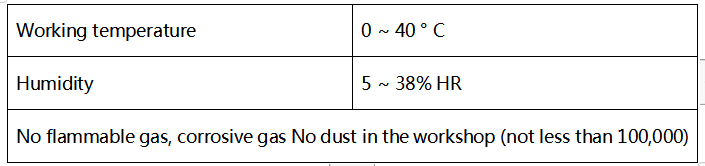

E. TechnicF. Use Environment

F. Use Environment

F. Use Environment

G. Quality Assurance and Guarantee

The equipment leaves the factory after installation and commissioning, and provides life-long maintenance services, training operators for you free of charge. Our company is ready to answer your questions and keep in touch with the testing machine at any time.

Remarks: Due to the large amount of orders during the epidemic period, component manufacturers may change. The right of interpretation belongs to our company.